SSU-12 Series SF6 Gas Insulated Ring Network Switchgear

Seven Star Electric was established in 1995. It is a national high-tech enterprise dedicated to the research, development and production of electric insulation products and high-voltage transmission and distribution products. The main products of the company include ring network cabinets, production and development of smart grid software and hardware (primary and secondary fused column switches, intelligent stations, power clairvoyance, etc.), cable branch boxes, low-voltage complete sets of equipment, cable connectors, cold shrink cable accessories, insulators, lightning arresters, etc. The company has a registered capital of RMB 130 million, fixed assets of RMB 200 million and more than 600 employees. The company has registered capital of 130-million-yuan, fixed assets of 200 million yuan and more than 600 employees. 2021, the company will achieve a turnover of 810 million yuan and tax revenue of nearly 30 million yuan. 2022, the annual output value is expected to exceed 1 billion yuan. The company's products have been sold to Vietnam, Philippines, Brazil, South Africa, Singapore, Malaysia and other countries.

In 2022, Quanzhou Tian chi Electric Import & Export Trading Co., Ltd. will be established to serve overseas customers.

Our fully insulated intelligent ring network cabinets cover SF6 gas insulated series, solid insulated series and environmental protection gas insulated series. After research and development, design and manufacture, we are fully equipped with the production capacity of standardized ring network cabinets and have obtained relevant third-party test reports.

At present, they are widely used in distribution systems with high power supply reliability requirements, such as urban commercial centers, industrial concentrated areas, airports, electrified railroads and high-speed highways.

Altitude

≤4000m (Please specify when the equipment operates at an altitude above 1000m so that the inflation pressure and the strength of the air chamber can be adjusted during manufacture).

Ambient temperature

Maximum temperature: +50°C;

Minimum temperature: -40°C;

The average temperature in 24h does not exceed 35℃.

Ambient Humidity

24h relative humidity not exceeding 95% on average;

The monthly relative humidity does not exceed 90% on average.

Application Environment

Suitable for highland, coastal, alpine and high filth areas; Seismic intensity: 9 degrees.

| No. | Standard No. | standard name |

|

1 |

GB/T 3906-2020 | 3.6kV~40.5kV AC metal-enclosed switchgear and control equipment |

|

2 |

GB/T 11022-2011 | Common technical requirements for high voltage switchgear and control gear standards |

|

3 |

GB/T 3804-2017 | 3.6kV~40.5kV high voltage AC load switch |

|

4 |

GB/T 1984-2014 | High voltage AC circuit breaker |

|

5 |

GB/T 1985-2014 | High Voltage AC Disconnectors and Earthing Switches |

|

6 |

GB 3309-1989 | Mechanical test of high voltage switchgear at room temperature |

|

7 |

GB/T 13540-2009 | Seismic Requirements for High Voltage Switchgear and Controlgear |

|

8 |

GB/T 13384-2008 | General technical requirements for packaging of mechanical and electrical products |

|

9 |

GB/T 13385-2008 | Packaging Drawing Requirements |

|

10 |

GB/T 191-2008 | Packaging, storage and transportation icons |

|

11 |

GB/T 311.1-2012 | Insulation coordination - Part 1 Definitions, principles and rules |

Compact

High Flood

Small Volume

LIght Weight

Maintenance Free

Fully Insulated

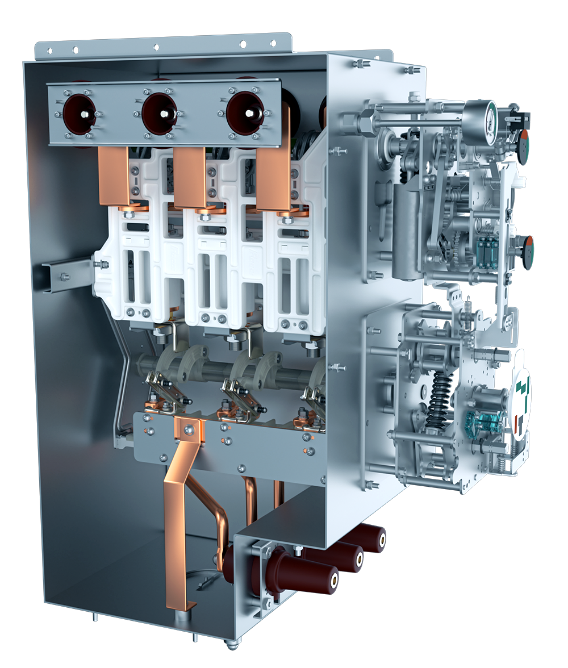

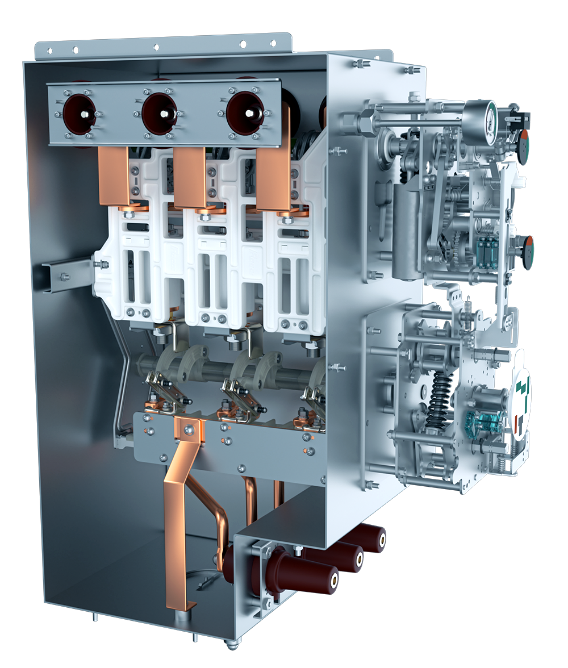

SSU-12 Series SF6 Gas Insulated Ring Network Cabinet Overview

· The gas tank of SSU-12 series SF6 gas insulated ring network cabinet adopts high –quality

2.5mm thick stainless-steel shell. The plate is formed by laser cutting and automatically

welded by an advanced welding robot to ensure the airtightness of the air box.

· The gas tank is filled with SF6 gas through synchronous vacuum leak detection, and the switch

activities such as load switch, grounding switch, fuse insulating cylinder, etc.

· Components and bus bars are sealed in a stainless-steel air box, with compact structure, strong

flood resistance, small size, light weight, maintenance-free, and full insulation.

· The protection level of the air box reaches IP67, and it is not affected by condensation, frost, salt spray, pollution, corrosion, ultraviolet rays and other substances.

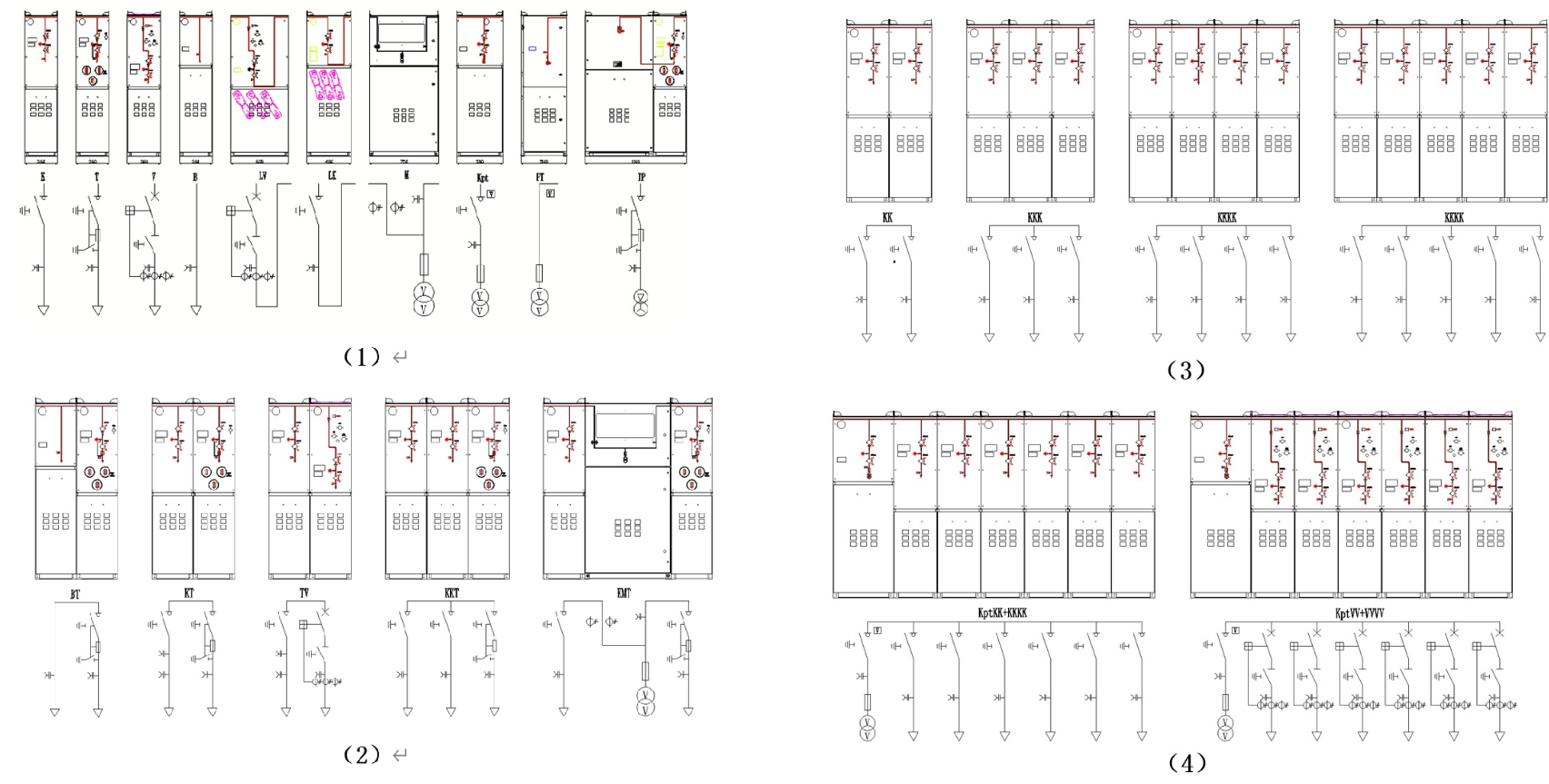

· Various main wirings are realized by combining different modules to form a circuit switch system;

the busbar

· Connector is used to realize the arbitrary expansion of the cabinet body; fully shielded cable inlet and outlet lines.

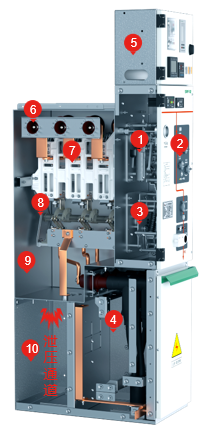

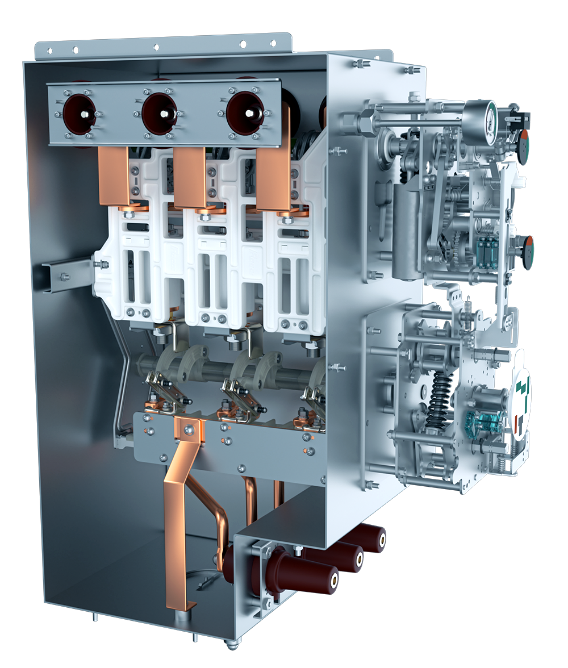

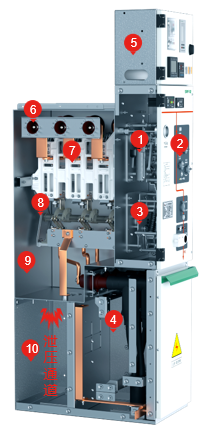

Major component arrangement

① Main switch mechanism ② Operation Panel ③ isolation agency

④ Cable Warehouse ⑤ Secondary control box ⑥ Busbar connection sleeves

⑦ Arc extinguishing device ⑧ Isolation switch ⑨ Fully enclosed box

⑩ Internal pressure relief device of the box

Cable Warehouse

- The cable compartment can only be opened if the feeder has been isolated or grounded.

- The bushing conforms to DIN EN 50181, M16 bolted, and the lightning arrester can be attached to the rear of the T-cable head.

- The one-piece CT is located on the side of the casing, making it easy to install cables and is not affected by external forces.

- The height of the casing installation to the ground is greater than 650mm.

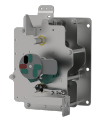

Breaker mechanism

The precision transmission mechanism with reclosing function adopts V-shaped key connection, and the shaft system support of the transmission system adopts a large number of rolling bearing design schemes, which are flexible in rotation and high in transmission efficiency, thus ensuring the mechanical life of the product for more than 10,000 times. Can be installed and maintained at any time.

Solation Mechanism

Single spring double operating shaft design, built-in reliable closing, opening, grounding limit interlocking device, to ensure that closing and opening without obvious overshoot phenomenon. The mechanical life of the product is more than 10,000 times, and the electrical components are designed in front, which can be installed and maintained at any time.

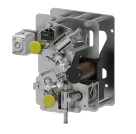

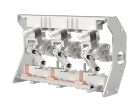

Arc extinguishing devices and disconnect switches

The cam structure of the closing and dividing device, over travel and full travel are accurate in size and have strong production compatibility. Insulation side plate adopts SMC molding process, with precise size and high insulation strength.

The isolation switch is designed with three stations for closing, dividing and grounding, which is safe and reliable.

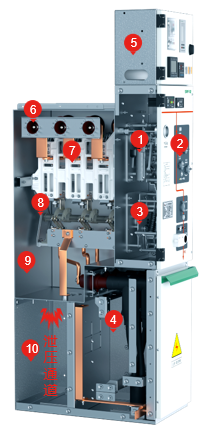

Main component arrangement

1. Load switch mechanism 2. Operation Panel

3. Cable Warehouse 4. Secondary control box

5. Busbar connection sleeves 6. Three-position load switch

7. Fully enclosed box 8. Internal pressure relief device of the box

Cable Warehouse

-The cable compartment can only be opened if the feeder has been isolated or grounded.

-The bushing conforms to DIN EN 50181, M16 bolted, and the lightning

Arrester can be attached to the rear of the T-cable head.

-Integrated CT is located on the side of the casing for easy cable

installation and is not affected by external forces.

-The height of the casing installation to the ground is greater than 650mm.

Three-position load switch

The closing, opening and grounding of the load switch adopt a three-position design, which is safe and reliable. Rotary blade + arc extinguishing grid arc extinguishing, with good insulation performance and breaking performance.

Load switch mechanism

Single spring double operation axis design, built-in reliable closing, breaking, grounding limit interlocking device, to ensure that the closing and breaking without obvious overshoot phenomenon. The mechanical life of the product is more than 10,000 times, and the front design of electrical components can be retrofitted and maintained at any time.

Main component arrangement

1.Combined electrical mechanism 2. Operation Panel 3. Three-position load switch

4. Cable Warehouse 5. Secondary control box 6. Busbar connection sleeves

7. Fuse cartridge 8. Lower grounding switch 9. Fully enclosed box

Cable Warehouse

-The cable compartment can only be opened if the feeder has been isolated or grounded.

-The bushing conforms to DIN EN 50181, M16 bolted, and the lightning arrester can be attached to the rear of the T-cable head.

-Integrated CT is located on the side of the casing for easy cable installation and is not affected by external forces.

-The height of the casing installation to the ground is greater than 650mm.

Three-position load switch

The closing, opening and grounding of the load switch adopt a three-position design, which is safe and reliable. Rotary blade + arc extinguishing grid arc extinguishing, with good insulation performance and breaking performance.

Combined electrical mechanism

The combined electrical mechanism with quick opening (tripping) function adopts the design of double springs and double operating shafts, and built-in reliable closing, opening, and grounding limit interlocking devices to ensure that there is no obvious overshoot phenomenon in closing and opening. The mechanical life of the product is more than 10,000 times, and the electrical components are designed in front, which can be installed and maintained at any time.

Lower ground switc

When the fuse is blown, the lower ground can effectively eliminate the residual charge on the transformer side and ensure personal safety when replacing the fuse.

Fuse cartridge

The three-phase fuse cylinders are arranged in an inverted structure, and are completely sealed with the gas box surface by a sealing ring, which can ensure that the switch operation will not be affected by the external environment. When the fuse of any one phase is blown, the striker triggers, and the quick release mechanism trips quickly to open the load switch, so as to ensure that the transformer will not have the risk of phase loss operation.

Products categories

- Online